Our skills in numerical simulations

Specific models

Non-standard sollicitations

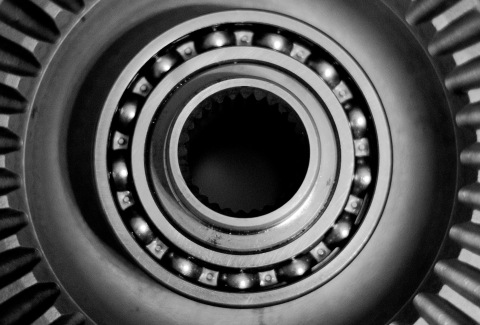

Tight screws can experience non-standard sollicitations that cannot be taken into account by the analytical calculations.

Thermal expansion

The assemblies can be submitted to thermal expansion originating in non-homogeneous temperature field.

Overlay of solicitations

The stress field generated by the screw connections can overlap locally to another field generated by an external load.

Screw tightening torque

It is sometimes necessary to master the screw tightening torque consumption due to tensions and friction losses between the different involved contacts.

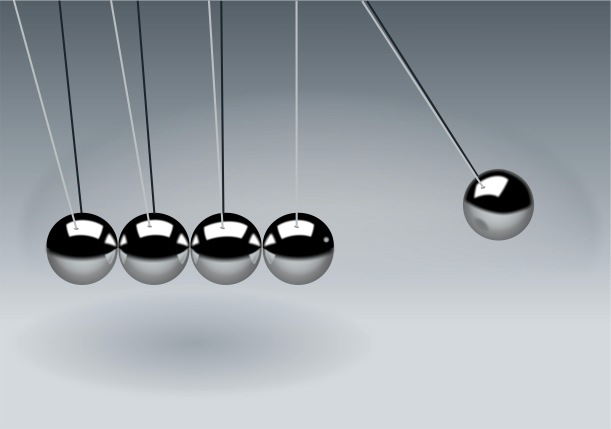

Subjection to shocks

Assemblies can be subjected to shocks, challenging the screw holding by another physical phenomenon than typically envisioned by the analytical criteria.

Over 15 years of experience

The expertise of AROBAS Technologies in these models results from over 15 years of experience on complex matters involving screw assemblies.

Fr

Fr  En

En